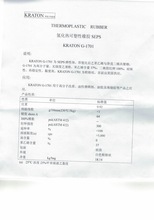

SEPS/United States Kraton/G1701 cosmetics, make-up powder high viscosity plastics

SEBS is using polystyrene as the end section, in order to get the hydrogenation of polybutadiene ethylene butene copolymer as the intermediate linear elastic block three block copolymer. SEBS does not contain unsaturated double bonds, so it has good stability and aging resistance.

purpose

1.SEBS has a good UV stability, anti oxygen and thermal stability, so the roof and road asphalt can also be used in.

There is good compatibility between 2.SEBS and paraffin wax, so it can be used as a flexible surface coating for paper products.

3.SEBS is not sensitive to shear flow when heated, so it can be used as a template for IPN. (the basic principle of IPN: two non miscible polymers, which can reach the mutual penetration of entangled chain segments, so that the two non miscible polymers can be "locked" together by covalent linkage.

Organic solution 4.SEBS oil blends can replace natural latex surgical gloves and manufacturing products, because SEBS does not contain unsaturated double bonds and high purity, and this has the following two advantages: (1) oxygen resistance, ozone resistance is good; (2) containing protein in natural rubber, which will make the risk of allergic reaction in some patients, and this will not blend.

在线聊天

在线聊天