The PCB is designed to be

smaller, faster and cheaper.As the interconnection point is the weakest link in

the circuit chain, the electromagnetic property at the interconnection point is

the main problem faced by the engineering design in the RF design. Every

interconnection point should be investigated and the existing problems solved.

Interconnection of PCB system

includes chip to PCB, interconnection of PCB board and signal input/output

between PCB and external device.This paper mainly introduces the practical

summary of high frequency PCB design by interconnection in PCB board. It is

believed that the understanding of this paper will bring convenience to PCB

design in the future.

Interconnection between chip

and PCB is important in PCB design. However, the main problem of

interconnection between chip and PCB is that too high interconnection density

will lead to the basic structure of PCB materials becoming a factor limiting

the growth of interconnection density.This article shares the practical

techniques of high frequency PCB design.For high frequency applications, the

following techniques are used to design high frequency PCB with interconnection

in PCB boards:

1, the transmission line to the corner a 45 ° Angle, in order to

reduce return loss;

2. High performance insulation

circuit board shall be strictly controlled by insulation constant value

according to hierarchy.This method is beneficial to the effective management of

the electromagnetic field between the insulating material and the adjacent

wiring.

3. Improve the PCB design

specifications for high precision etching.Consider setting the total line width

error to +/-0.0007 inches, managing undercut and cross sections of the wire

shape, and specifying the conditions for side wall plating of the wire.The

overall management of the geometry and coating surfaces of wiring (wires) is

very important for solving the skin effect related to microwave frequency and

realizing these specifications.

4. Highlight the presence of

tap inductor in the lead, and avoid the use of components with lead.In high

frequency environments, it is best to use surface mounted components.

5. For signal perforation,

avoid using PTH process on sensitive plate.Because this process will lead to

lead inductance at the hole.For example, when a hole in a 20-layer plate is

used to connect 1 to 3 layers, the lead inductor can affect 4 to 19 layers.

6. Provide a rich seam

connection.A die hole is used to connect these layers together to prevent the

impact of a 3-dimensional electromagnetic field on the circuit board.

7. To choose non-electrolytic

nickel plating or dip plating process, do not use HASL method for plating.This

electroplating surface can provide a better skin effect for high frequency

current.In addition, the high solderable coating requires less lead wire and

helps reduce environmental pollution.

8. The welding resistance layer

can prevent the soldering paste from flowing.However, due to the uncertainty of

thickness and the uncertainty of insulation performance, covering the entire

plate surface with welding resistance materials will lead to a large change in

electromagnetic energy in microstrip design.Solderdam is commonly used as the

resistance layer.

·

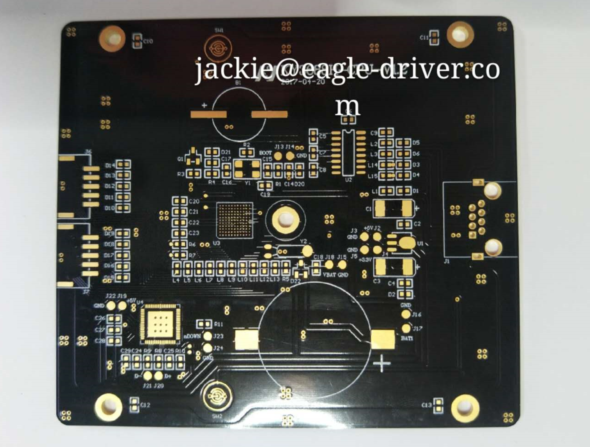

EAGLE DRIVER ELECTRONIC LIMITED--Outstanding

in PCB production.